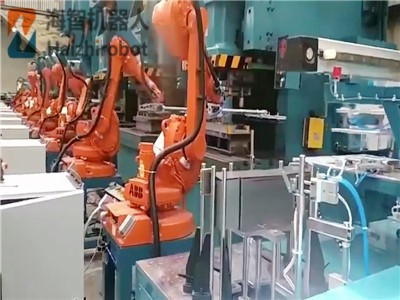

海智多工位沖壓機器人系列

海智單工(gong)(gong)(gong)(gong)(gong)位沖(chong)(chong)壓(ya)(ya)(ya)機(ji)器人(ren)(ren)(機(ji)械(xie)手)是指--沖(chong)(chong)床(chuang)工(gong)(gong)(gong)(gong)(gong)序(xu)只(zhi)(zhi)有一道進行(xing)自(zi)(zi)動化(hua)改(gai)造(zao)的(de)時候簡稱單工(gong)(gong)(gong)(gong)(gong)位或(huo)者單工(gong)(gong)(gong)(gong)(gong)序(xu),無論(lun)是有多工(gong)(gong)(gong)(gong)(gong)序(xu)拆分或(huo)者只(zhi)(zhi)有一個工(gong)(gong)(gong)(gong)(gong)序(xu)只(zhi)(zhi)要(yao)是只(zhi)(zhi)有一臺沖(chong)(chong)床(chuang)應用自(zi)(zi)動化(hua)工(gong)(gong)(gong)(gong)(gong)業機(ji)械(xie)手改(gai)造(zao)生產(chan)的(de)都(dou)叫單工(gong)(gong)(gong)(gong)(gong)位沖(chong)(chong)壓(ya)(ya)(ya)機(ji)器人(ren)(ren)。如多個工(gong)(gong)(gong)(gong)(gong)序(xu)組(zu)成的(de)沖(chong)(chong)壓(ya)(ya)(ya)自(zi)(zi)動化(hua)改(gai)造(zao)則為(wei)多工(gong)(gong)(gong)(gong)(gong)位沖(chong)(chong)壓(ya)(ya)(ya)機(ji)械(xie)手或(huo)者機(ji)械(xie)手生產(chan)線聯機(ji);海智在沖(chong)(chong)床(chuang)沖(chong)(chong)壓(ya)(ya)(ya)領域(yu)可根據不同的(de)產(chan)品參數、生產(chan)工(gong)(gong)(gong)(gong)(gong)藝和情況進行(xing)專業評估(gu)與(yu)選型。

沖(chong)壓自動化改造通常使用四軸機(ji)械(xie)手(關節式或者擺臂(bei)式)如產品需要進行翻(fan)轉面沖(chong)壓則需要五軸或者六軸機(ji)械(xie)手;

單(dan)工位沖(chong)壓通常使(shi)(shi)用一臺是(shi)使(shi)(shi)用一臺機械手實現根據需求效率的增加(jia)可以使(shi)(shi)用兩臺沖(chong)壓機器人完成來增加(jia)生(sheng)產(chan)的效率。

四軸沖壓機器人生產線(xian)

擺臂式沖壓機(ji)械手生產線

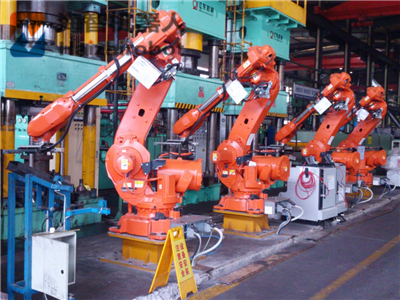

沖床拉伸機械(xie)手(shou)生產線(數(shu)控沖床與液壓拉伸沖床聯機生產)

六軸(zhou)沖壓(ya)機器人生產線(多工位拉伸沖床和數(shu)控沖床)

一、性能(neng)穩(wen)定

(全伺服電機(ji)減(jian)速機(ji)配(pei)置(zhi))機(ji)器(qi)人(ren)(ren)使(shi)用應(ying)用成熟穩(wen)定(ding)配(pei)置(zhi)使(shi)沖壓機(ji)器(qi)人(ren)(ren)更加高(gao)效、穩(wen)定(ding)、無故障。

二、編(bian)程(cheng)(cheng)簡易、示教編(bian)程(cheng)(cheng)

點對點的編程操作簡單易學,包教(jiao)會。

三、兼容性(xing)高

可通用于不同類型(xing)生產,滿足通用性(xing)。

四、性價比(bi)高

海智(zhi)沖(chong)壓機器人在(zai)穩定、編(bian)程(cheng)、維護等方面(mian)都(dou)有明(ming)顯(xian)的優勢,性價比高(gao)。

五、減少工傷

沖(chong)床(chuang)沖(chong)壓屬于高風險行(xing)業(ye),而使用沖(chong)壓機(ji)器人無(wu)論(lun)是單機(ji)或是聯機(ji),操作(zuo)人員手部都(dou)在模具和沖(chong)床(chuang)工作(zuo)范圍外的(de)安全區域(yu),更安全。